production

and processing

The raw material arrives to our warehouse in borosilicate glass tubes. It can be in different diameter sizes and thicknesses, as well as characterized by different finishes, which can be smooth, internally or externally ribbed.

The glass work process is divided in multiple steps.

Step 1

The first phase consists in the division of the various types of pipes and in the choice of the line to be created.

Therefore, we proceed with its transformation into long phials. These are produced by hand or by means of a specific machinery, and represent the basis for subsequent processing.

Step 2

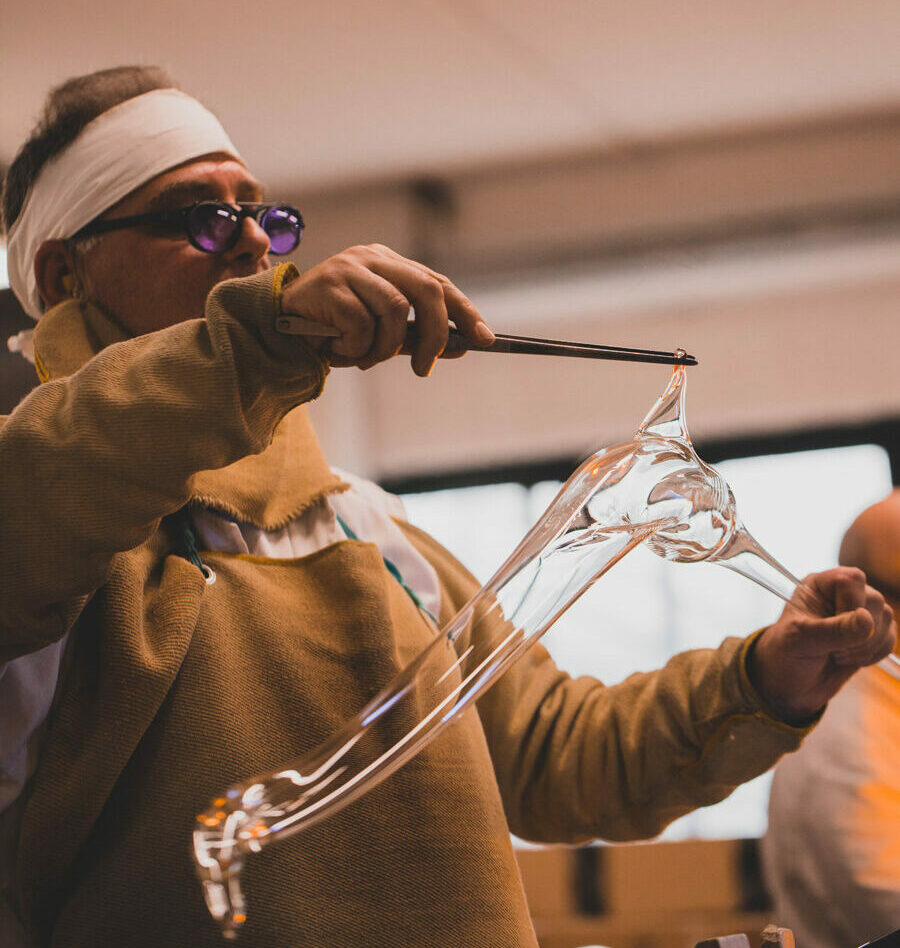

The second step consists on phial’s manufacturing: warming it up to about 1.300°C using special torches powered up by propane gas and oxygen. Through this process it is possible to work the material into various shapes.

In fact, at these temperatures, the glass becomes highly ductile and malleable, so it is possible to proceed with its modification, so it can be cut, bent, blown, reduced, choked, extended, opened, assembled by melting and processing the matter.

Following these processes, the piece is fired at 600°C for hardening and therefore its stabilization.

Step 3

The third step consists in customizing the finishes of the object created.

The glass is born transparent, but thanks to the finishing process it is possible to embellish the object. The achievable finishes are:

- Spray and brush painting in the colors: amber, ruby, smoky, green, blue, rose, orange

- Brush finish in 24K gold, platinum or copper

- Mirror effect, a particular inner mirror painting treatment of the object

- Frosted opal effect, with a white opal base but which can be painted to take on different shades and effects

- Decal transfer, it is the application, in a film, of personalized logos, brands, signatures directly to the product

The finishing goal is to personalize and make the product even more refined. All customers can personalize their product as preferred in order to receive an original and unique piece.

Step 5

Finally, the last phase includes a test to verify the quality and functionality of the finished product. If the product passes this test then it is prepared for packaging and shipping.

Some products can be also decorated with a composition of fragrant pot-pourri of different colors, as well as finished with fine satin ribbons and beautiful brooches.

Then we proceed with the packaging of the products and the preparation for shipment.

Every piece is packed in safe way to avoid any damage during transportation.